An alternative Volvo Brake conversion

I read with much interest about the Volvo brake conversion shown on the 311s.org site. I decided it was the way to go when I cracked open the stock calipers and found the expected rust. Called a buddy at NAPA, and he gave me his best price on the Volvo calipers, but said he couldn't do a thing about the $40 each core charge. I tracked down a Volvo only boneyard where I bought two rusted calipers for $4 - yes four dollars - made the 45 min. round trip very worth while. Had the rotors cut down and faced

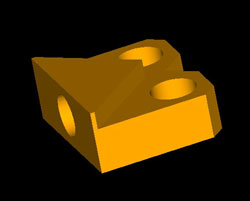

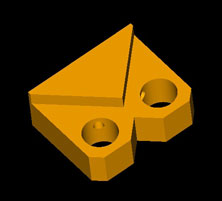

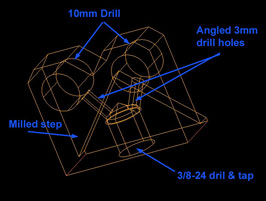

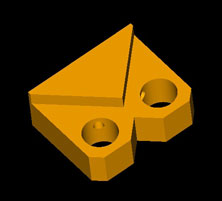

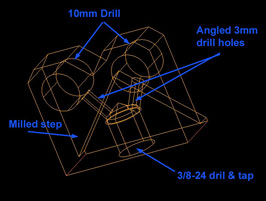

While looking at the pictures on the 311s site, I got to thinking that there might be an alternative to the tightly bent tubing - having just redone most of the hydaulic lines, I shuddered at the prospect. I took some measurements off the calipers and surroundings, and came up with the idea for a "manifold block". A single inlet feeds the two caliper "ports". A "V" shaped clearance cut accommodates the machining on the caliper, while avoiding any fancy CNC programming.

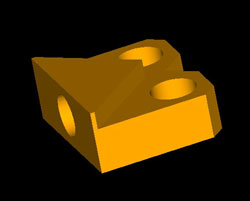

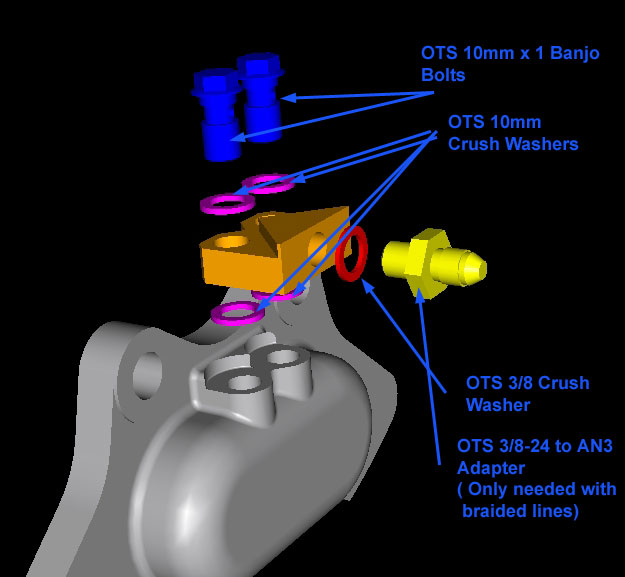

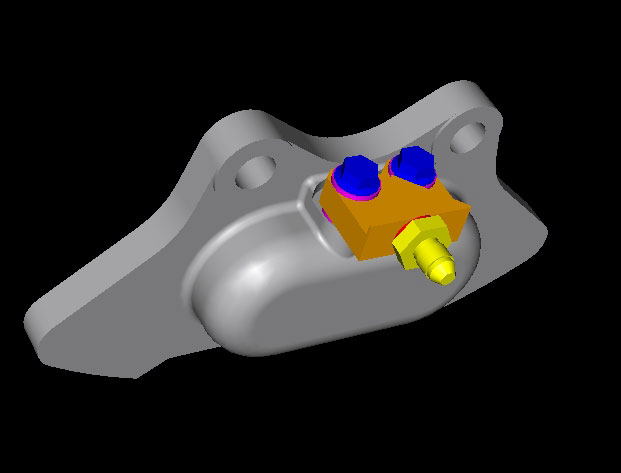

The adapter fits to the caliper as shown in this assembly, using OTS (off the shelf) hardware. It allow the use of either the stock rubber line, or a -3AN braided SS line using an adapter.

Parts Needed:

Summit Racing

Earl's Banjo bolts - part# EAR-997517

Banjo Bolt replacement washers - part# EAR-177100

If you want SS lines-

Pegasus Racing

3AN* to Female 42° Inverted Flare 3/8-24 . . . . . . . . . . . . . .Part No. 3265-12* . . . . . . $4.49

3AN to 3/8-24*, large hex for crush washer . . . . . . . . . . . . . Part No. 3265-26* . . . . . . $4.99

14" -3straight to -3straight Stainless brake line . . . . . . . . . .Part No.

3-14-S-S . . . . . $14.99

I had planned on milling and drilling a set for myself. Thanks to Roadster List member Steve Allen and his machinist friend who volunteered to machine up a couple sets, here are some pics of it installed. I love it when a plan comes together. The SS lines in the pics are 16" long, but I'll be returning them for 14" parts which will be plenty long for travel and steering.

Some caveats:

I have tested the set made for me, which match the dimensions given in the drawing below, using only parts with the part numbers listed above - there may be dimensional differences in other brands of banjo bolts or crush washers which may affect fit and or sealing. Also, compare the calipers you are buying with the illustration above - one guy who went to install a set of these found differences between the two calipers he had. One of them did not have the machined flats surrounding the tapped holes - these are necessary to get the manifold block to seal. Might have been an aftermarket part, or casting from a later year, so be sure the ones you're getting have the flats before you walk out with them.

The assembly sequence is to mount the blocks to the calipers FIRST, torqueing them to 180-200 inch lbs. They must be TIGHT in order for the washers to crush properly. To get enough leverage, use a length of 1x3 pine or 3/4"plywood between the pads to hold the caliper steady.

Keeping the wood between the pads, squirt the fittings with soapy water and bench test for leaks using high pressure air through a rubber tipped blow nozzle.

Then mount the caliper to the car - it may be necessary to skiff off a corner of the face of the head on one or both banjo bolts, depending on casting flash on the steering knuckle. I had to file a bit off one bolt on one side caliper to seat. Rather take material off the thick head of the bolt, than possibly create a stress riser in the knuckle.

Hook up all the fittings and lines, then pressure test the system for leakage - these are your brakes we're talking about and hence any leaks can compromise your ability to STOP! If you do find any leaks, you'll have to drop the caliper to re-tighten the banjos.

For anyone interested in making, or having some machined up, here's the drawing. If you click on it, there a hi-res printable version 300dpi. If you have SERIOUS interest in a set of these adapters, email me. I don't have any sitting on the shelf, and the set-up fees for a machine shop to make them onesy-twosy would make them very expensive, but if there's enough commitment - read "advance deposit", the guy who made these might be enticed to make more. Otherwise, feel free to use the drawing and have a friend of a friend make 'em for you.